Methods for Repairing Difficult-to-Remove Track Roller Shafts (Compiling Relevant Maintenance Techniques):

I. Pre-Disassembly Preparation

Cleaning and Pressure Relief

Thoroughly remove mud and debris around the roller to prevent interference during operation.

If the equipment is equipped with a tensioning cylinder, first loosen the pressure relief plug to release track tension (loosen no more than one turn to prevent high-pressure grease spray).

Supporting the Equipment

Lift the chassis using the boom cylinder to suspend the track, facilitating operation.

II. Core Disassembly Methods

Standard Disassembly (Light Corrosion)

Uniform Percussion Method: Use a copper rod or soft metal pad to strike uniformly around the shaft circumference, avoiding deformation from single-point impact. Strikes must be precise and moderate in force.

Pull Tool Application:

Use a dedicated puller (e.g., hydraulic ram/puller) secured to the roller shaft, applying pulling force gradually for removal.

If standard tools fail, upgrade to a 20-40 ton puller to avoid damaging components by forcing.

Handling Severe Corrosion or Seizure

Thermal Expansion Method:

Use an oxy-acetylene torch to heat the shaft sleeve or bearing area evenly (~200°C), leveraging metal expansion differences to loosen rust. Then use a puller for removal.

CAUTION: Avoid high temperatures burning seals; act quickly after heating.

Cutting Method (Last Resort):

If the shaft is beyond salvage, carefully cut the bearing or shaft sleeve using an oxy-fuel cutter (protect surrounding structures), taking approximately 40-50 minutes.

Dealing with Seized Bolts

Check bolt condition before disassembly: If severely corroded, first heat the bolt hole (e.g., localized heating with a torch), then attempt loosening; if stripped, specialized extraction tools are required.

During reinstallation, use extended bolts (double the original length) for easier future maintenance.

III. Operational Precautions

Safety Protection:

Keep flammable materials away during heating; wear fire-resistant gear. Wear safety goggles during percussion.

Avoid Component Damage:

Never strike the shaft end or bearing balls directly with a hammer to prevent deformation and scrap.

Leverage Mechanics:

Place hard wood blocks under the roller and use pry bars for slow prying, combined with the pulling force of a puller for disassembly.

IV. Post-Repair Recommendations

Anti-Corrosion Treatment:

Apply anti-corrosion grease or molybdenum disulfide to the new shaft before installation to reduce future seizure risk.

Routine Maintenance:

After operating in sandy/muddy environments, promptly clean the track system and check the tightness of roller bolts.

Key Challenge Note: If disassembly remains impossible after self-attempts (e.g., severe shaft deformation or insufficient tools), contact a professional repair team or the equipment manufacturer to prevent further losses.

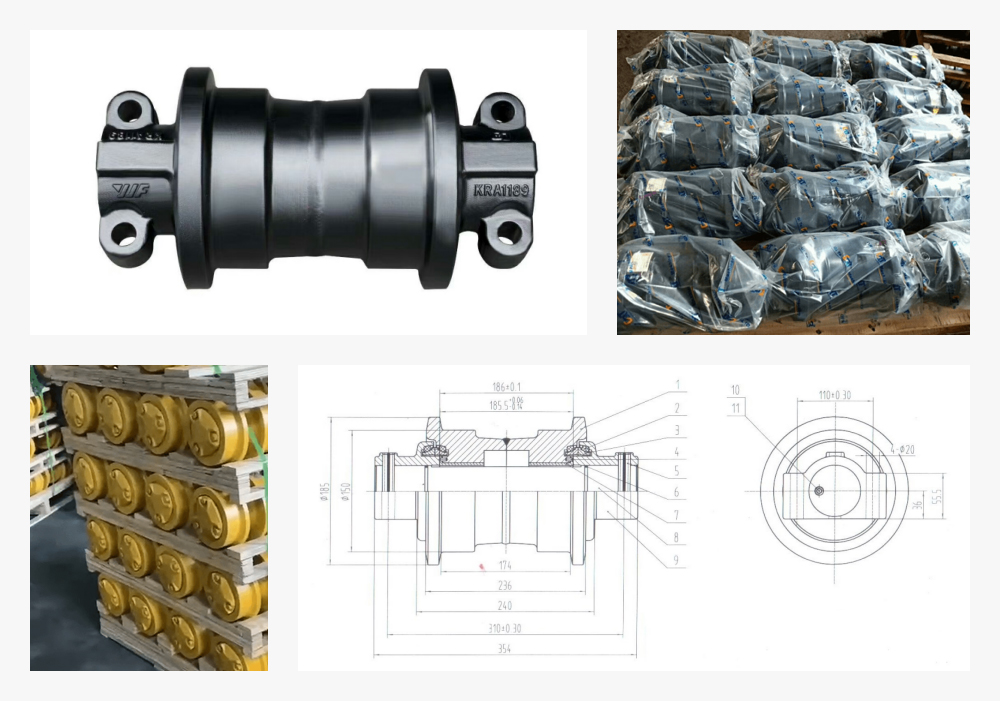

For track roller inquiries, please contact us via the details below

Helly Fu

E-mail: [email protected]

Phone: +86 18750669913

Whatsapp: +86 18750669913

Post time: Jun-09-2025