I. Pre-Replacement Preparations

Site Selection

Requires solid and level ground (e.g., concrete), avoiding soft or sloped terrain to prevent equipment tipping.

Tool Preparation

Essential tools: Torque wrench (recommended 270N·m specification), hydraulic jack, chain hoist, pry bar, copper drift, high-strength track shoe bolts.

Safety gear: Hard hat, anti-slip gloves, goggles, safety support rods.

Equipment Securing

Turn off the engine and engage the parking brake. Secure the non-replaced side track with wooden wedges; use hydraulic support rods to stabilize the frame if necessary.

II. Excavator Track Shoe Removal Process

Release Track Tension

Loosen the tensioning cylinder grease nipple to slowly drain hydraulic oil until the track slackens (sag >5cm).

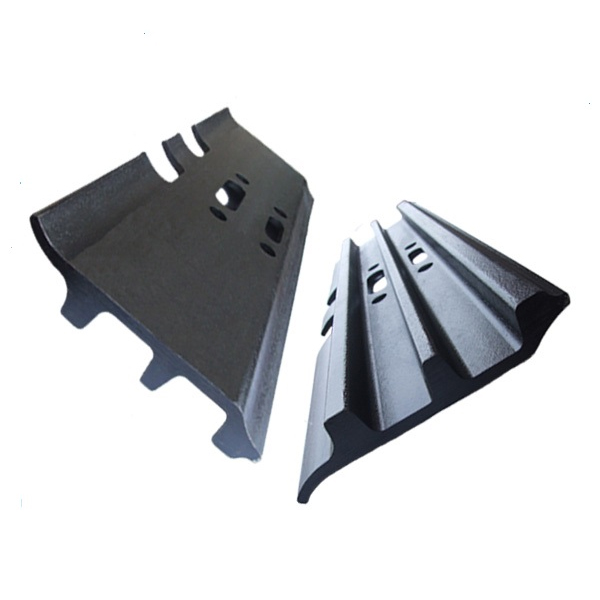

Remove Old Excavator Track Shoes

Clear mud/debris from track gaps (high-pressure water jet recommended).

Loosen bolts counterclockwise with a torque wrench; apply penetrating oil or cut severely corroded bolts.

Remove bolts alternately to prevent stress concentration on chain links.

III. New Excavator Track Shoe Installation

Alignment

Precisely align new track shoes with chain link holes. Insert track pins and finger-tighten bolts initially.

Torque Bolt Tightening

Tighten bolts in diagonal sequence twice:

First: 50% standard torque (~135N·m)

Second: 100% standard torque (270N·m).

Apply thread-locking adhesive to prevent vibration-induced loosening.

IV. Debugging & Inspection

Adjust Track Tension

Inject grease into the tensioning cylinder, lift one track 30-50cm off the ground, and measure sag (3-5cm). Excessive tension accelerates wear; insufficient tension risks derailment.

Test Run

Idle tracks for 5 minutes. Check for abnormal noises/jamming. Re-inspect bolt torque and chain engagement.

Critical Notes

Safety First: Prohibited to initiate travel with tracks suspended. Wear protective gear throughout disassembly.

Bolt Management: Mandatory use of OEM-strength bolts; reuse of old bolts prohibited.

Lubrication: Apply water-resistant grease (NLGI Grade 2+) to chain pins after installation.

Operational Adaptation: Avoid heavy loads/steep slopes for the first 10 hours. Check bolt status daily during break-in.

Tip: For complex conditions (e.g., chain link wear) or hydraulic system faults, consult professional technicians.

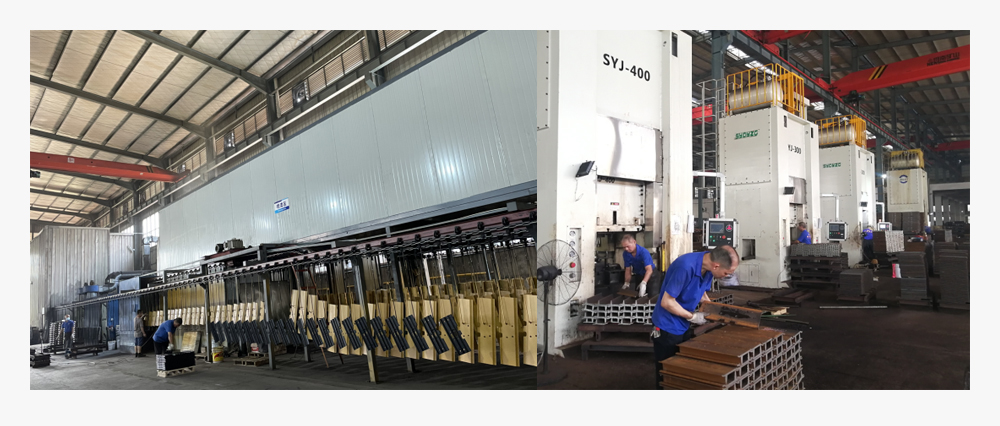

For track shoe inquiries, please contact us via the details below

Helly Fu

E-mail: [email protected]

Phone: +86 18750669913

Wechat / Whatsapp: +86 18750669913

Post time: Jun-16-2025