The track shoe, one of the undercarriage parts of construction machinery, is a wear part. It is mainly used in excavator, bulldozer, crawler crane.

The track shoe can be divided as steel type and rubber type. The steel track shoe is used in the large tonnage equipment. The rubber track pad is used in the small tonnage equipment.

The most commonly used for steel track shoe is excavator track shoe and bulldozer track shoe.The excavator track shoe is triple grouser track shoe. Generally it is black. The bulldozer track shoe is single grouser track shoe. Generally it is yellow.

The wider the track shoe, the higher the pressure on the links between the pins and the bushings. A track shoe that is too big will increase the wear process of the caterpillar chain and consequently the chance of a chain breakage.

A track shoe should be adjusted to the terrain on which the machine is working. The wider the track shoe, the lower the ground pressure per cm2 , but the greater the wear on the entire running mechanism.

The raw material is 25MNB.

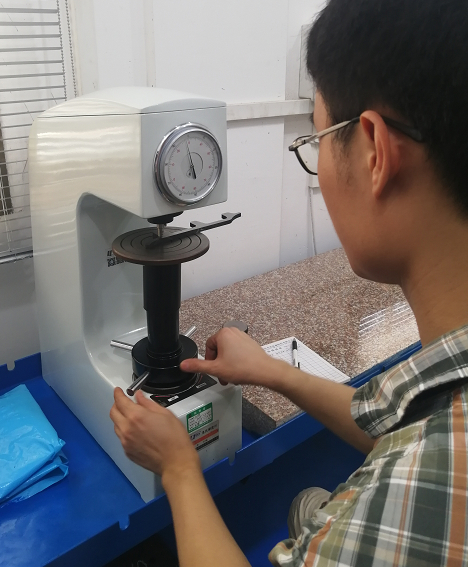

The hardness is about HRC42-49. The hardening process is the guarantee for high wear resistance.

This energetic company focuses on manufacturing excavator and bulldozer spare parts – track shoe,track roller, carrier roller, sprocket, idler,track bolt,bucket bushing & pin etc. The high-quality products are recognized in the industry, and are sold to Europe and America, the Middle East, Southeast Asia and other countries.

Yongjin Machinery has strict control over complete manufacturing line for cutting material, hole punching, heat treatment, shot blasting and painting.

Yongjin Machinery has a professional inspection team and a perfect inspection system. Every track shoe takes strict inspection procedure before shipment.

We make the normative product quality standard and inspection standard.

All our products conform to this standards.

Post time: Aug-16-2022